Things about Motorcycle Parts New Zealand Specialists

Motorcycle Parts New Zealand Specialists for Beginners

Table of ContentsTop Guidelines Of Motorcycle Parts New Zealand SpecialistsAll about Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals ExplainedMotorcycle Parts New Zealand Specialists - The FactsThe Of Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists - Truths6 Easy Facts About Motorcycle Parts New Zealand Specialists ShownThe Single Strategy To Use For Motorcycle Parts New Zealand Specialists

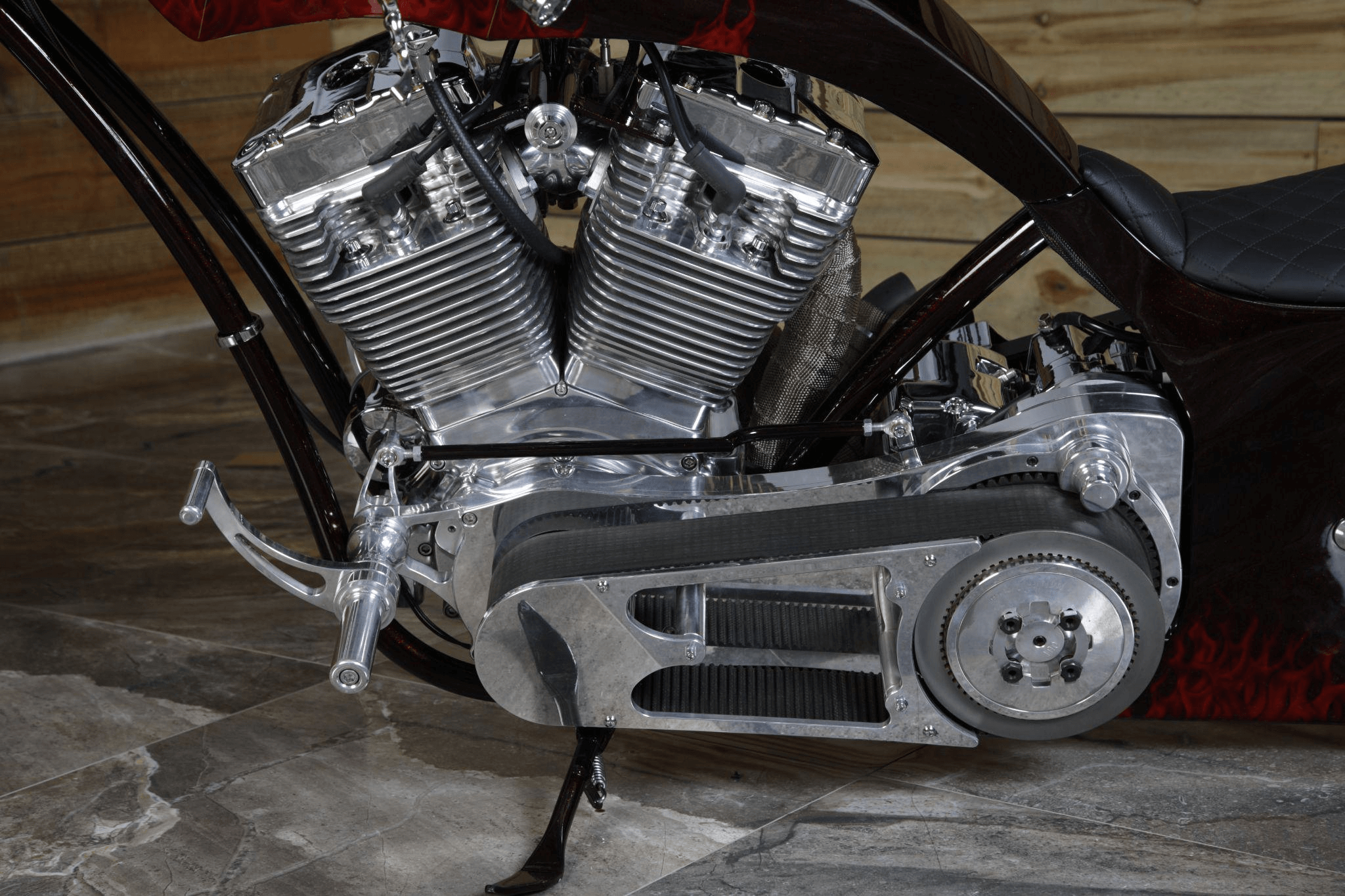

So, connect to among our specialists today.CNC machining technology is quickly becoming the prime focus of various manufacturing processes around the world as a direct result of its lots of benefits over other techniques. Furthermore, the sectors that manufacture bikes have actually gotten on board with this pattern. One of the most innovative firms are now creating their engine parts and wheels utilizing machining methods initially established for motorbike components.

You may be asking yourself why we use. Currently that we have your focus let us describe the rationale behind this modern advancement in the bike manufacturing market.

The 15-Second Trick For Motorcycle Parts New Zealand Specialists

In addition, you have full control over the look of the parts, even down to the minute details. Sometimes, motorcyclists might decide to spruce up their adventure by installing aftermarket parts or changing the bike's transformation.

See This Report on Motorcycle Parts New Zealand Specialists

CNC machining may be made use of to make nearly all of a bike's steel and plastic parts. To proceed, we'll talk about a number of machined components for bikes. In comparison to those on automobiles, wheels on bikes tend to be more noticeable. Because of this, the bike's appearances may be improved with the proper personalization of these wheels.

When tailoring the wheels, the disks are where the emphasis must be. Most of them are constructed of aluminum. Light weight aluminum alloys are well-known for the impressive machining abilities that they possess. Milling procedures are made use of to get the desired degree of wheel customization. An additional facet of the motorcycle that might be customized is the tires.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

When it pertains to an automobile (or a motorcycle), the most crucial part is the engine. Several people mention it as the "heart" of the auto. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be complex and require styles with a high degree of precision.

Usage only high-grade things, nevertheless, considering that these lights are important for the safety of motorcyclists and various other motorists or people on the roadway, especially at evening. Motorcycle fronts lights have three major parts: the bulb, or light source, the lens, and the housing.

Milling processes with a flawless surface would result in the lenses having a reflective high quality that resembles that of a mirror. The cover, on the various other hand, is not composed of fragile materials; instead, it is built out of hard polymers that can be machined into more elaborate patterns.

Some Of Motorcycle Parts New Zealand Specialists

Motorbike manufacturers frequently cast these components, however just for the production of bespoke components. Machining on five axes in today's world is the means by which any type of style form might be recognized.

Select Runsom for your personalized bike components! We have the ability to produce difficult and fashionable elements making your motorcycle incomparable.

Right here are a couple of examples of steels often utilized in bike component machining. Aluminum is the key material made use of by companies focusing on generating personalized bike components to develop the majority of these parts. In the past, we would certainly construct our engines out of actors iron. On the other hand, aluminum is quickly coming to be the product of choice, partly due to the fact that it is a lot more lightweight.

Zinc refers to one more metal that is very light in weight and has great machining top qualities due to its high mechanical stamina. This material may be developed into almost any kind of form and keeps its dimensions well. Also mission-critical elements that require a high level of accuracy may take advantage of their usage.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

An additional metal that sees hefty use in the manufacturing of CNC-customized components is magnesium. It is among the lightest steels that are currently obtainable and has exceptional machinability functions and stamina appropriate with its reduced weight. One of the disadvantages of magnesium is that its dirt might easily catch fire.

Their most common use in creating different Related Site bike components is fasteners, such as screws and bolts. Their reduced sensitivity to oxidation and corrosion makes them excellent for this usage.

The Buzz on Motorcycle Parts New Zealand Specialists

It appears that CNC turning and crushing are the fundamental processes. In enhancement, it needs keeping bars of material, most frequently plastic or steel, in placement and after that twisting a cutting device to eliminate areas of the product as the product is transformed.

These approaches are similarly essential and produce components with high precision and regular quality. They are respectively: grinding, laser cutting, and drilling. The term "surface area coating" describes post-processes after the first machining stage. Motorcycle Parts New Zealand Specialists. The processes aid boost the total high quality of the machined bike elements. Below are the quick introduction, benefits and drawbacks of 5 surface treatment methods.

An Unbiased View of Motorcycle Parts New Zealand Specialists